Diseño de experimentos para mejorar los parámetros de proyección de recubrimientos de YSZ mediante proyección por plasma atmosférico

Palabras clave:

recubrimientos de YSZ, APS, parámetros de proyección, Diseño de experimentosContenido principal del artículo

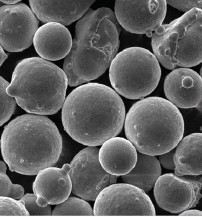

Objectives:To implement the Design of Experiments (DOE) methodology to obtain the projection parameters for the deposition of yttria-stabilized zirconia (YSZ) on Inconel 625 by atmospheric plasma spraying (APS).

Methodology:A 32 factorial design with three repetitions was implemented, in which the factors were the electrical current and the hydrogen flow rate. The response variables were the mean particle velocity and the particle temperature in flight. Coating quality was evaluated in terms of tetragonal phase content, porosity, and coating thickness.

Results:The samples deposited at 430 A and hydrogen flow rates of 7 and 9 NLPM exhibited the most outstanding characteristics. The sample deposited at 430 A and 7 NLPM of H₂ was subjected to thermal shock tests.

Conclusions:The sample deposited at 430 A and 7 NLPM of H₂ demonstrated superior performance compared to similar coatings reported in the scientific literature.

1. Chen L, Li B, Feng J. Rare-earth tantalates for next-generation thermal barrier coatings. Prog Mater Sci. 2024;144:101265. https://doi.org/10.1016/j.pmatsci.2024.101265

2. Sezavar A, Sajjadi SA. A review on the performance and lifetime improvement of thermal barrier coatings. J Eur Ceram Soc. 2025;45:117274. https://doi.org/10.1016/j.jeurceramsoc.2025.117274 DOI: https://doi.org/10.1016/j.jeurceramsoc.2025.117274

3. Chen L, Li B, Feng J. Rare-earth tantalates for next-generation thermal barrier coatings. Prog Mater Sci. 2024;144:101265. https://doi.org/10.1016/j.pmatsci.2024.101265 DOI: https://doi.org/10.1016/j.pmatsci.2024.101265

4. Lokachari S, Leng K, Rincon Romero A, Curry N, Brewster G, Norton A, Hussain T. Processing-Microstructure-Properties of Columns in Thermal Barrier Coatings: A Study of Thermo-Chemico-Mechanical Durability. ACS Appl Mater Interfaces. 2024;16:10646-10660. https://doi.org/10.1021/acsami.3c16681

5. Mehboob G, Liu M-J, Xu T, Hussain S, Mehboob G, Tahir A. A review on failure mechanism of thermal barrier coatings and strategies to extend their lifetime. Ceram Int. 2020;46:8497-8521. doi: https://doi.org/10.1016/j.ceramint.2019.12.200 DOI: https://doi.org/10.1016/j.ceramint.2019.12.200

6. Leng K, Romero AR, Curry N, Hussain T. Multilayer GZ/YSZ thermal barrier coating from suspension and solution precursor plasma spray. Ceram Int. 2024;50:631-649. https://doi.org/10.1016/j.ceramint.2023.10.142 DOI: https://doi.org/10.1016/j.ceramint.2023.10.142

7. Gómez JA, de la Roche J, Gómez P, Toro A. Influence of Iron Oxide Deposits on the Hot Corrosion Resistance of YSZ Thermal Barrier Coatings in Molten Vanadium Pentoxide. Materials and Corrosion. 2025; https://doi.org/10.1002/maco.202414673 DOI: https://doi.org/10.1002/maco.202414673

8. Jiang C, Hao W, Liu C, Shi D, Song W. Thermal cycling performance of GYbZ/YSZ thermal barrier coatings with different microstructures based on finite element simulation. J Alloys Compd. 2025;1010:177185. https://doi.org/10.1016/j.jallcom.2024.177185 DOI: https://doi.org/10.1016/j.jallcom.2024.177185

9. Vagge ST, Ghogare S. Thermal barrier coatings: Review. Mater Today Proc. 2022;56:1201-1216. https://doi.org/10.1016/j.matpr.2021.11.170 DOI: https://doi.org/10.1016/j.matpr.2021.11.170

10. Fu Y, Yao Z, Chen Y, Wang H, Li Y, Dong J. Progress in the Deposition Mechanisms and Key Performance Evaluation of Thermal Barrier Coatings for Turbine Blades: A Review. Acta Metallurgica Sinica (English Letters). 2025;38:177-204. https://doi.org/10.1007/s40195-024-01799-6 DOI: https://doi.org/10.1007/s40195-024-01799-6

11. Clarke DR, Oechsner M, Padture NP. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bull. 2012;37:891-898. https://doi.org/10.1557/mrs.2012.232 DOI: https://doi.org/10.1557/mrs.2012.232

12. Padture NP, Gell M, Jordan EH. Thermal Barrier Coatings for Gas-Turbine Engine Applications. Science (1979). 2002;296:280-284. https://doi.org/10.1126/science.1068609 DOI: https://doi.org/10.1126/science.1068609

13. Darolia R. Thermal barrier coatings technology: critical review, progress update, remaining challenges and prospects. International Materials Reviews [Internet]. 2013;58:315-348. https://doi.org/10.1179/1743280413Y.0000000019 DOI: https://doi.org/10.1179/1743280413Y.0000000019

14. Jiang XY, Hu J, Jiang SL, Wang X, Zhang LB, Li Q, Lu HP, Yin LJ, Xie JL, Deng LJ. Effect of high-enthalpy atmospheric plasma spraying parameters on the mechanical and wear resistant properties of alumina ceramic coatings. Surf Coat Technol. 2021;418:127193. https://doi.org/10.1016/j.surfcoat.2021.127193 DOI: https://doi.org/10.1016/j.surfcoat.2021.127193

15. Lokachari S, Leng K, Rincon Romero A, Curry N, Brewster G, Norton A, Hussain T. Processing-Microstructure-Properties of Columns in Thermal Barrier Coatings: A Study of Thermo-Chemico-Mechanical Durability. ACS Appl Mater Interfaces. 2024;16:10646-10660. https://doi.org/10.1021/acsami.3c16681 DOI: https://doi.org/10.1021/acsami.3c16681

16. Kebriyaei A, Rahimipour MR, Razavi M. Solution Medium Suspension Plasma Spray (SMSPS): A Microstructure and High-Temperature Properties Analysis of YSZ Thermal Barrier Coating. Journal of Thermal Spray Technology. 2024;33:2395-2407. https://doi.org/10.1007/s11666-024-01848-7 DOI: https://doi.org/10.1007/s11666-024-01848-7

17. Tsai PC, Hsu CS. High temperature corrosion resistance and microstructural evaluation of laser-glazed plasma-sprayed zirconia/MCrAlY thermal barrier coatings. Surf Coat Technol. 2004;183:29-34. https://doi.org/10.1016/j.surfcoat.2003.08.090 DOI: https://doi.org/10.1016/j.surfcoat.2003.08.090

18. Pakseresht AH, Kimiayi A, Alizadeh M, Nuranian H, Faeghinia A. Microstructural study and hot corrosion behavior of bimodal thermal barrier coatings under laser heat treatment. Ceram Int. 2020;46:19217-19227. https://doi.org/10.1016/j.ceramint.2020.04.259 DOI: https://doi.org/10.1016/j.ceramint.2020.04.259

19. Avci A, Karabaş M, Akdoğan Eker A, Akman E, Aslan C. Hot corrosion behavior of CYSZ thermal barrier coating with optimized laser surface modification. Ceram Int. 2023;49:31396-31404. https://doi.org/10.1016/j.ceramint.2023.07.087 DOI: https://doi.org/10.1016/j.ceramint.2023.07.087

20. Schneider KE, Belashchenko V, Dratwinski M, Siegmann S, Zagorski A. Thermal Spraying for Power Generation Components. WILEY-VCH. Weinheim: WILEY-VCH Verlag GmbH & Co.; 2006.

https://doi.org/10.1002/3527609342 DOI: https://doi.org/10.1002/3527609342

21. Witz G, Shklover V, Steurer W, Bachegowda S, Bossmann H. Phase evolution in yttria‐stabilized zirconia thermal barrier coatings studied by rietveld refinement of X‐ray powder diffraction patterns. Journal of the American Ceramic Society. 2007;90:2935-2940.

https://doi.org/10.1111/j.1551-2916.2007.01785.x DOI: https://doi.org/10.1111/j.1551-2916.2007.01785.x

22. De la Roche J, Gómez PA, Alvarado-Orozco JM, Toro A. Hot corrosion and thermal shock resistance of Dense-CYSZ/YSZ bilayer thermal barrier coatings systems applied onto Ni-base superalloy. J Eur Ceram Soc. 2020;0-1. https://doi.org/10.1016/j.jeurceramsoc.2020.07.004 DOI: https://doi.org/10.1016/j.jeurceramsoc.2020.07.004

23. De la Roche J, Alvarado-Orozco JM, Toro A. Hot corrosion mechanism of yttria-stabilized zirconia powder in the presence of molten Na2SO4 + V2O5 salts. Rare Metals. 2021;40:1307-1316. https://doi.org/10.1007/s12598-020-01388-3 DOI: https://doi.org/10.1007/s12598-020-01388-3

24. De la Roche J, Alvarado-Orozco JM, Gómez PA, Cano IG, Dosta S, Toro A. Hot corrosion behavior of dense CYSZ/YSZ bilayer coatings deposited by atmospheric plasma spray in Na2SO4 + V2O5 molten salts. Surf Coat Technol. 2022;432:128066. .

https://doi.org/10.1016/j.surfcoat.2021.128066 DOI: https://doi.org/10.1016/j.surfcoat.2021.128066

25. Khan AN, Lu J. Behavior of air plasma sprayed thermal barrier coatings, subject to intense thermal cycling. Surf Coat Technol. 2003;166:37-43. https://doi.org/10.1016/S0257-8972(02)00740-5 DOI: https://doi.org/10.1016/S0257-8972(02)00740-5

26. Jamali H, Mozafarinia R, Razavi RS, Ahmadi-Pidani R. Comparison of thermal shock resistances of plasma-sprayed nanostructured and conventional yttria stabilized zirconia thermal barrier coatings. Ceram Int. 2012;38:6705-6712. https://doi.org/10.1016/j.ceramint.2012.05.060 DOI: https://doi.org/10.1016/j.ceramint.2012.05.060

27. Nejati M, Rahimipour MR, Mobasherpour I, Pakseresht AH. Microstructural analysis and thermal shock behavior of plasma sprayed ceria-stabilized zirconia thermal barrier coatings with micro and nano Al2O3 as a third layer. Surf Coat Technol. 2015;282:129-138. https://doi.org/10.1016/j.surfcoat.2015.10.030 DOI: https://doi.org/10.1016/j.surfcoat.2015.10.030

28. Ahmadi-Pidani R, Shoja-Razavi R, Mozafarinia R, Jamali H. Improving the thermal shock resistance of plasma sprayed CYSZ thermal barrier coatings by laser surface modification. Opt Lasers Eng. 2012;50:780-786. https://doi.org/10.1016/j.optlaseng.2011.12.007 DOI: https://doi.org/10.1016/j.optlaseng.2011.12.007

29. Evans AG, Mumm DR, Hutchinson JW, Meier GH, Pettit FS. Mechanisms controlling the durability of thermal barrier coatings. Prog Mater Sci. 2001;46:505-553. https://doi.org/10.1016/S0079-6425(00)00020-7 DOI: https://doi.org/10.1016/S0079-6425(00)00020-7

30. Rabiei A, Evans AG. Failure mechanisms associated with the thermally grown oxide in plasma-sprayed thermal barrier coatings. Acta Mater [Internet]. 2000;48:3963-3976. https://doi.org/10.1016/S1359-6454(00)00171-3 DOI: https://doi.org/10.1016/S1359-6454(00)00171-3

Downloads

Esta obra está bajo una licencia internacional Creative Commons Atribución-NoComercial-CompartirIgual 4.0.

Los autores que publican en esta revista están de acuerdo con los siguientes términos:

Los autores ceden los derechos patrimoniales a la revista y a la Universidad del Valle sobre los manuscritos aceptados, pero podrán hacer los reusos que consideren pertinentes por motivos profesionales, educativos, académicos o científicos, de acuerdo con los términos de la licencia que otorga la revista a todos sus artículos.

Los artículos serán publicados bajo la licencia Creative Commons 4.0 BY-NC-SA (de atribución, no comercial, sin obras derivadas).